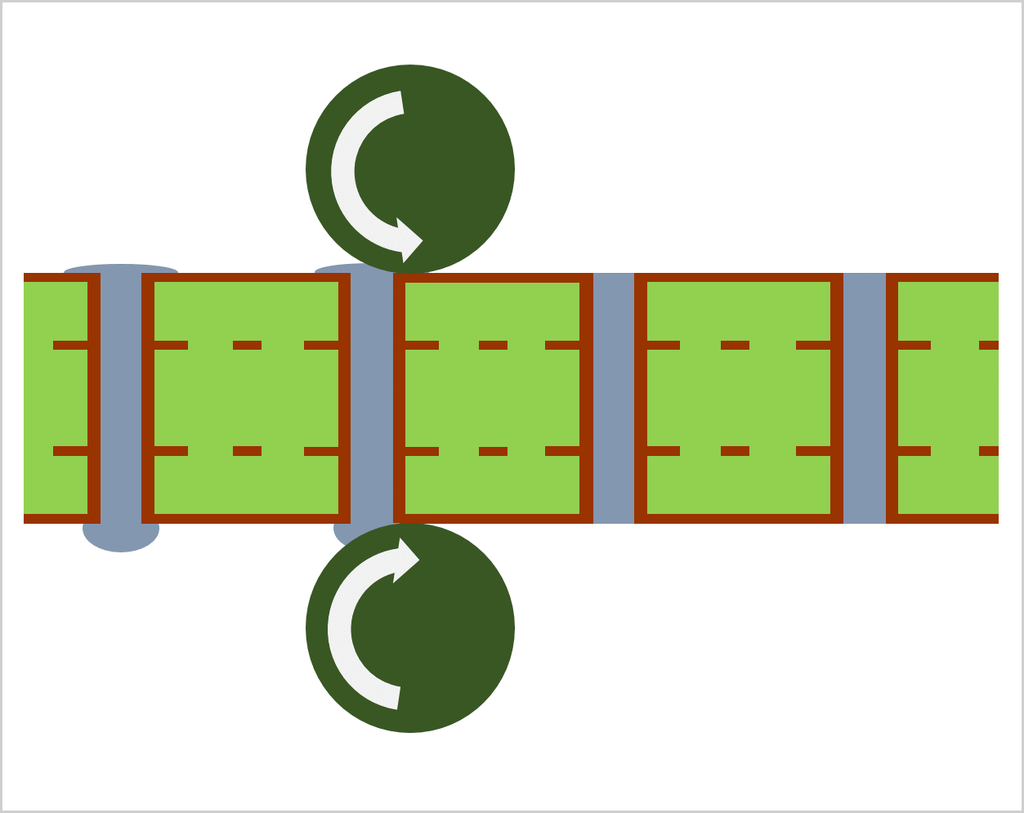

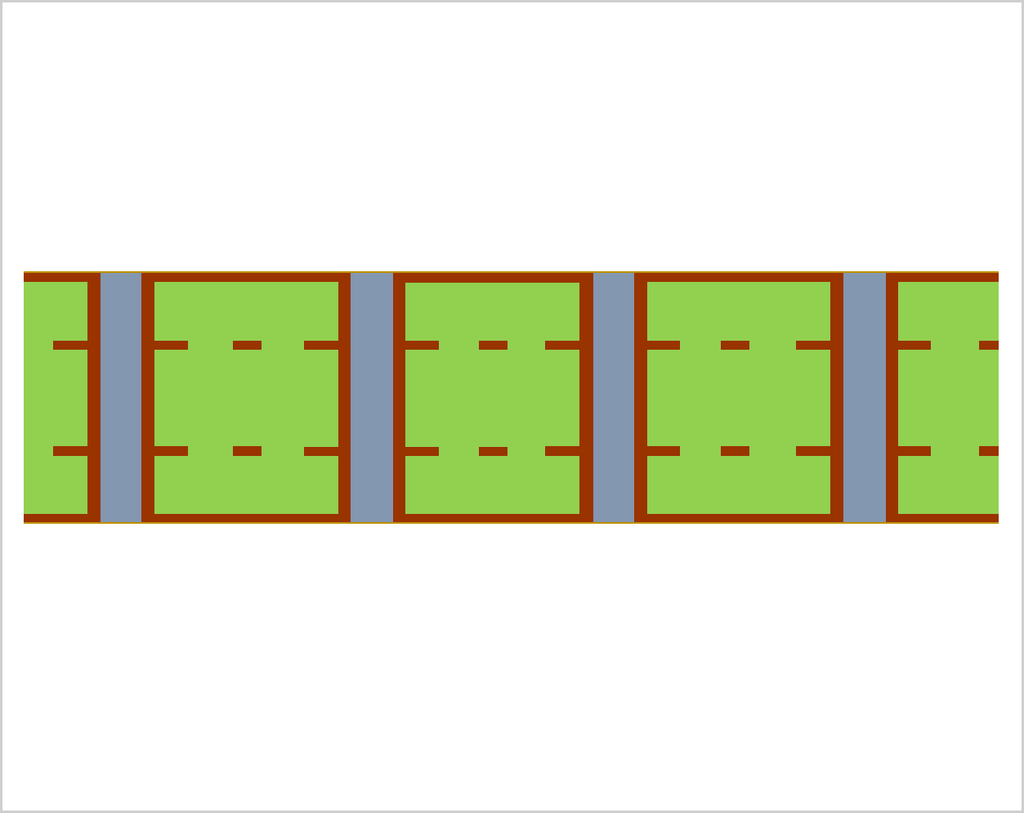

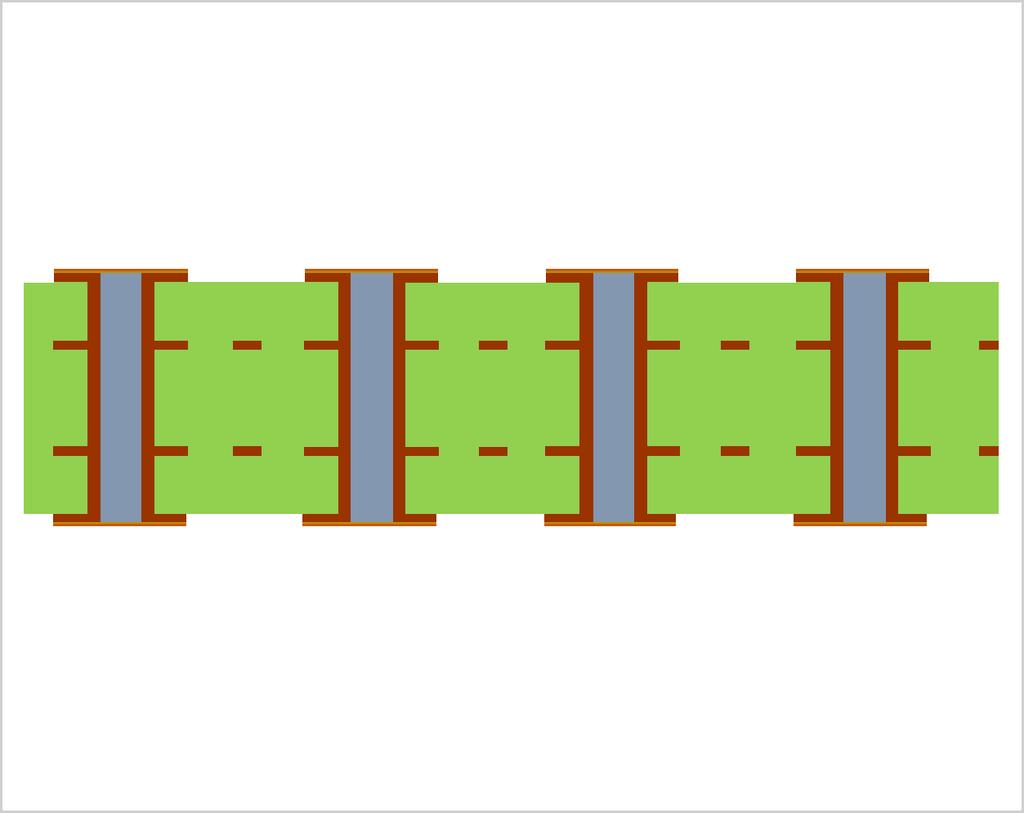

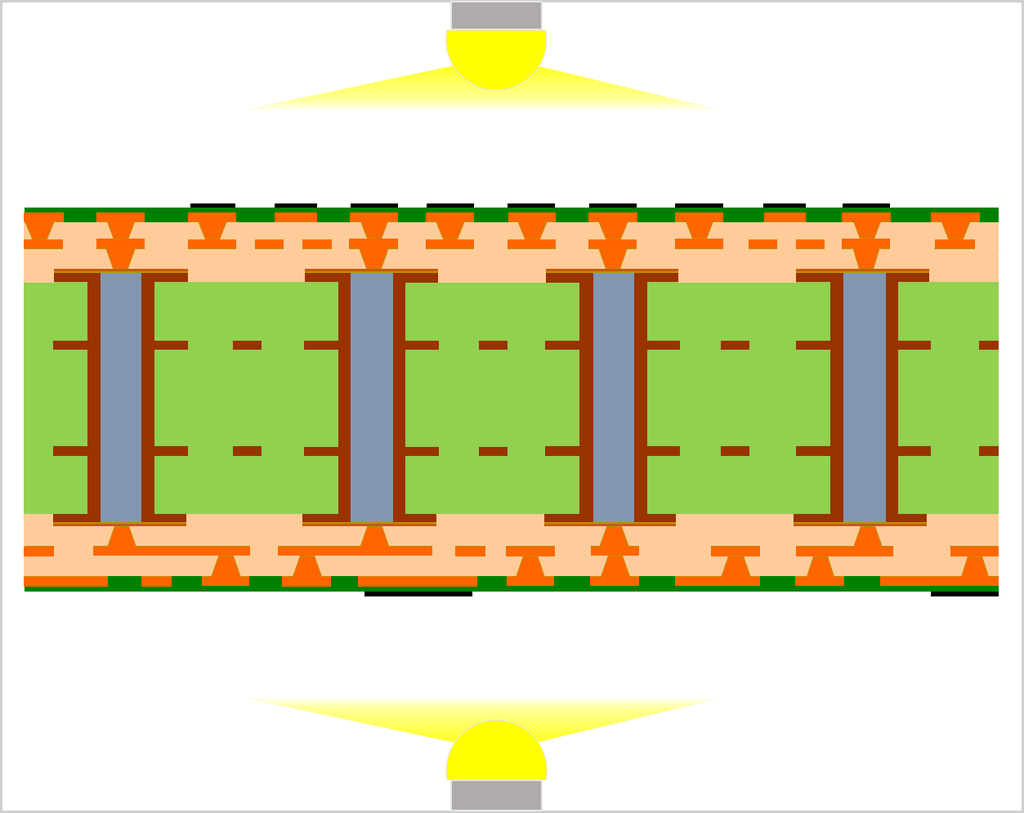

Plug-in into through holes

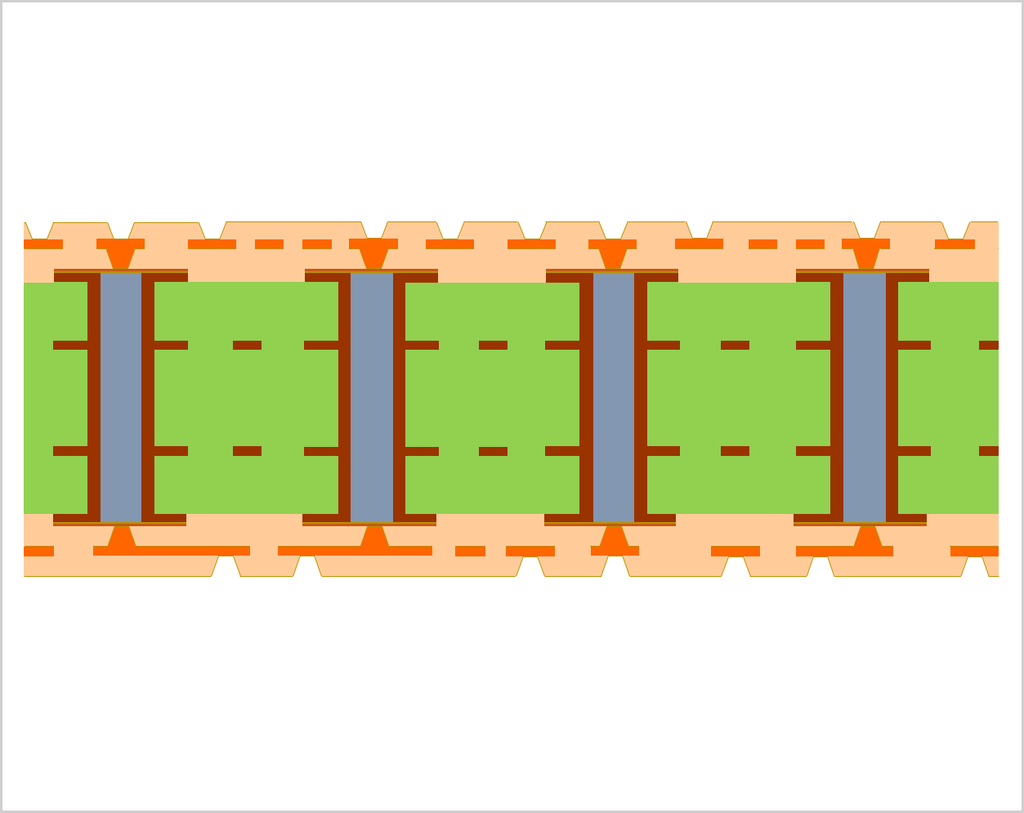

Multi-layer (ex. 4 or 6 layer) printed wiring boards are used as the core for semiconductor substrates. Here, we start detailed explanation about the manufacturing process after the copper electroplating step into through holes. You can learn more information before the copper electroplating into through holes by our website, "Contribute PWB fabrication by OKUNO’s total solutions".

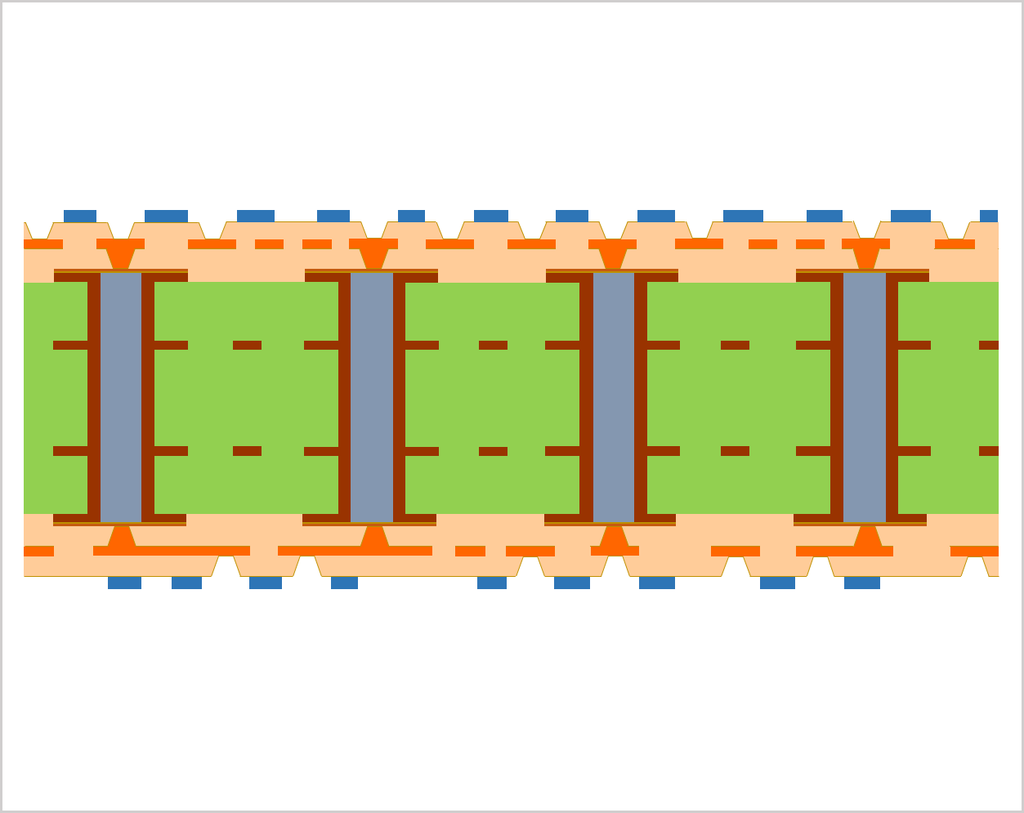

Roughen copper electroplating surface by annealing or other methods.

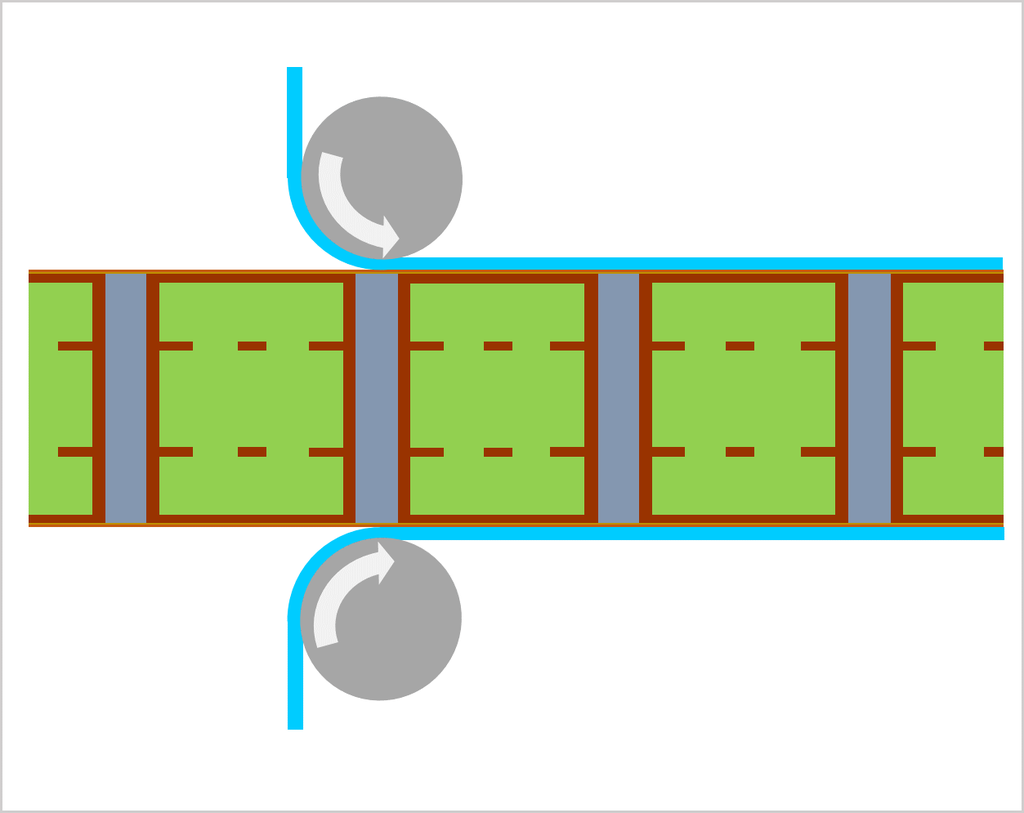

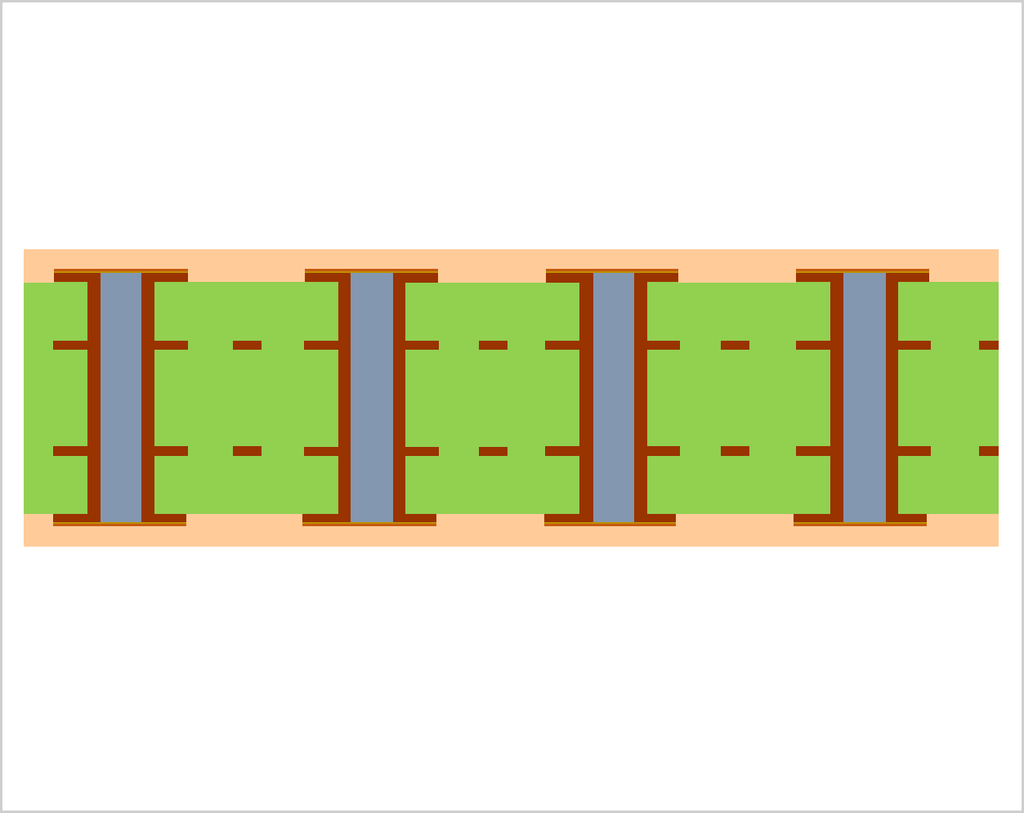

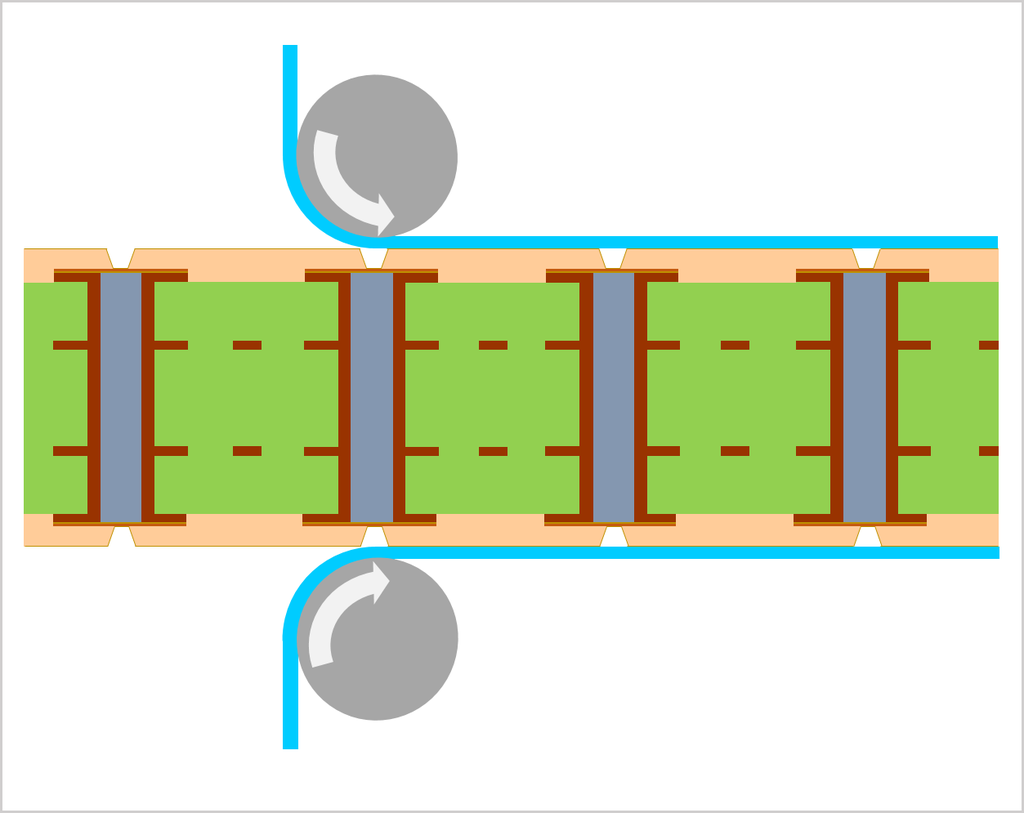

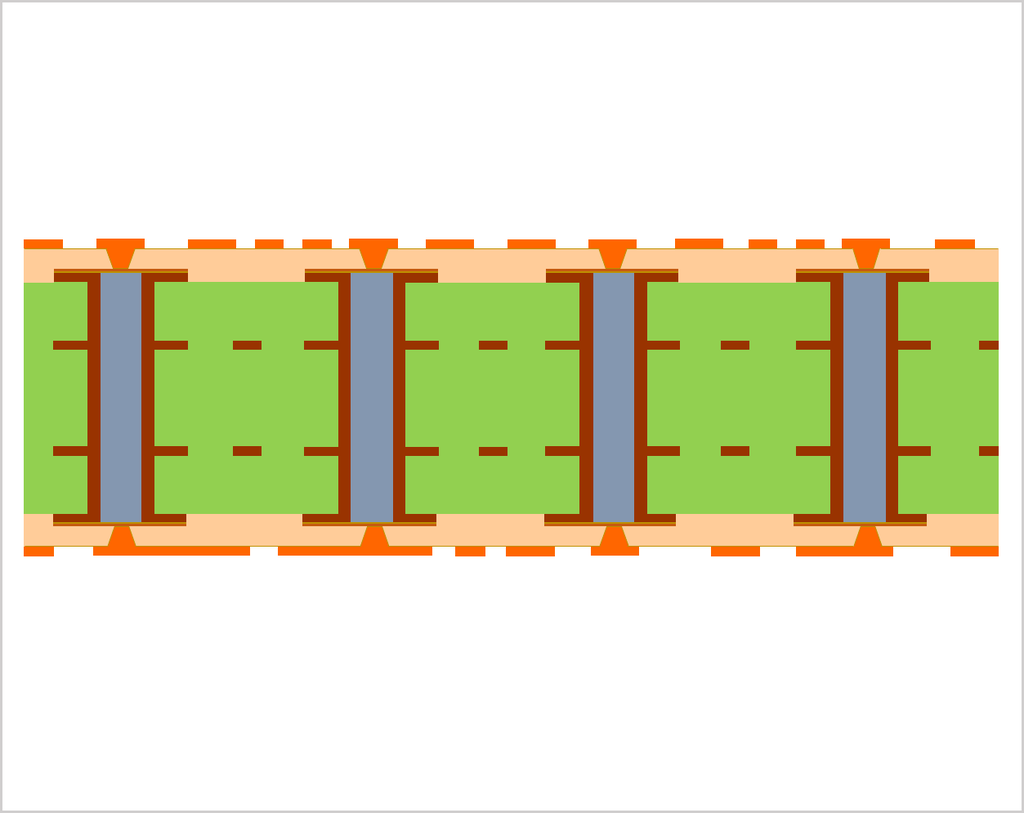

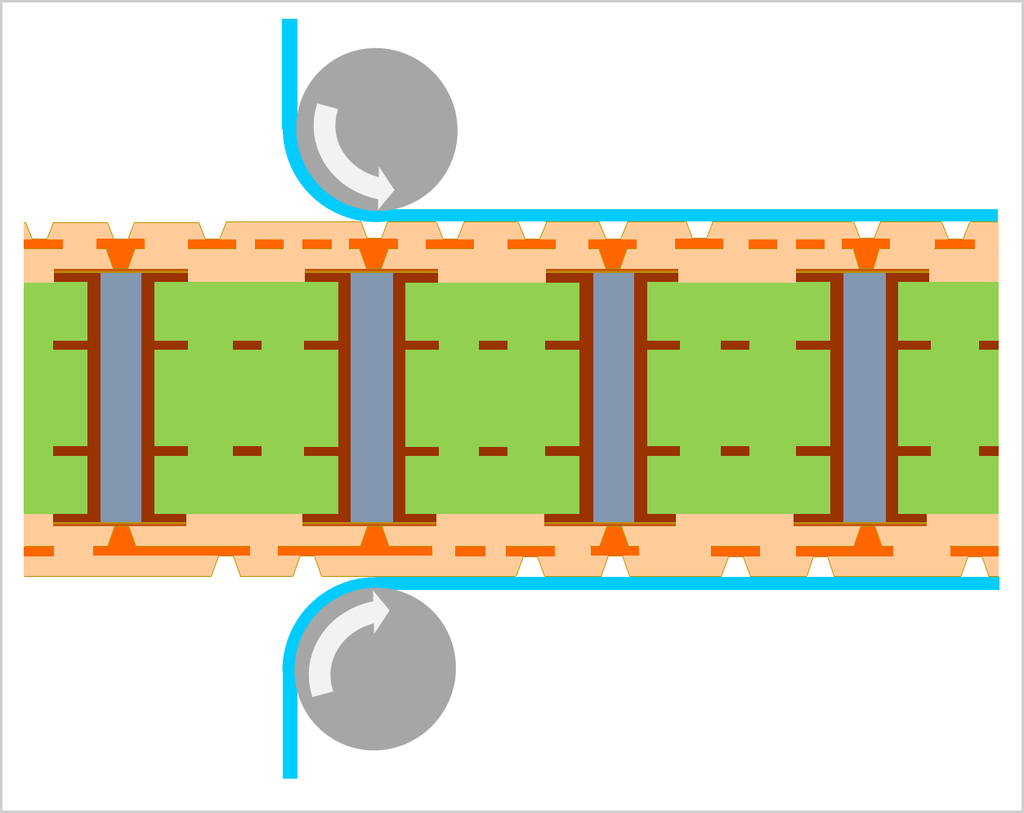

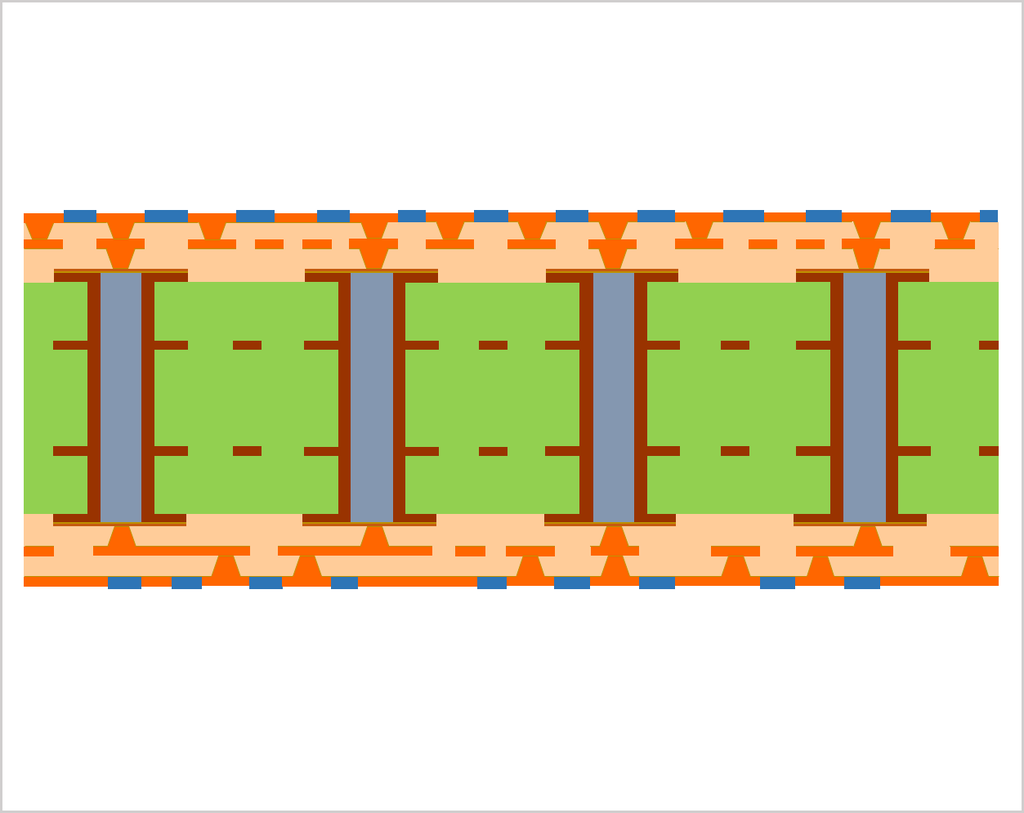

Fill each through holes with thermosetting inks (Hole Plugging Process).

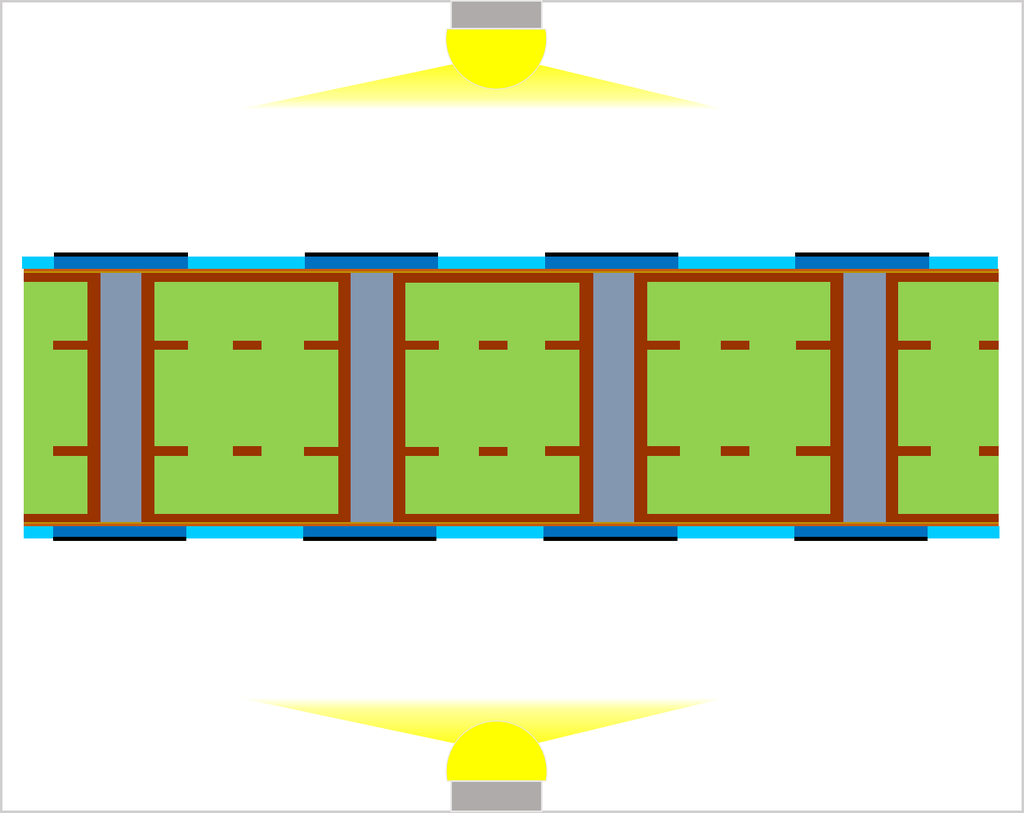

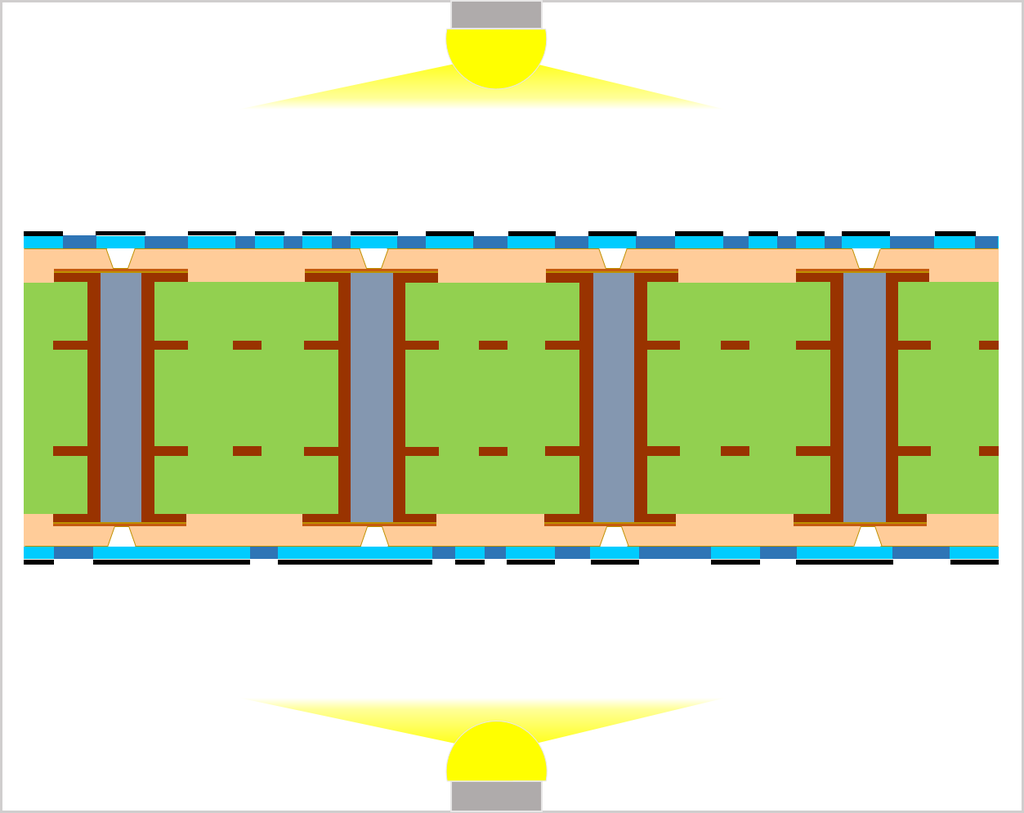

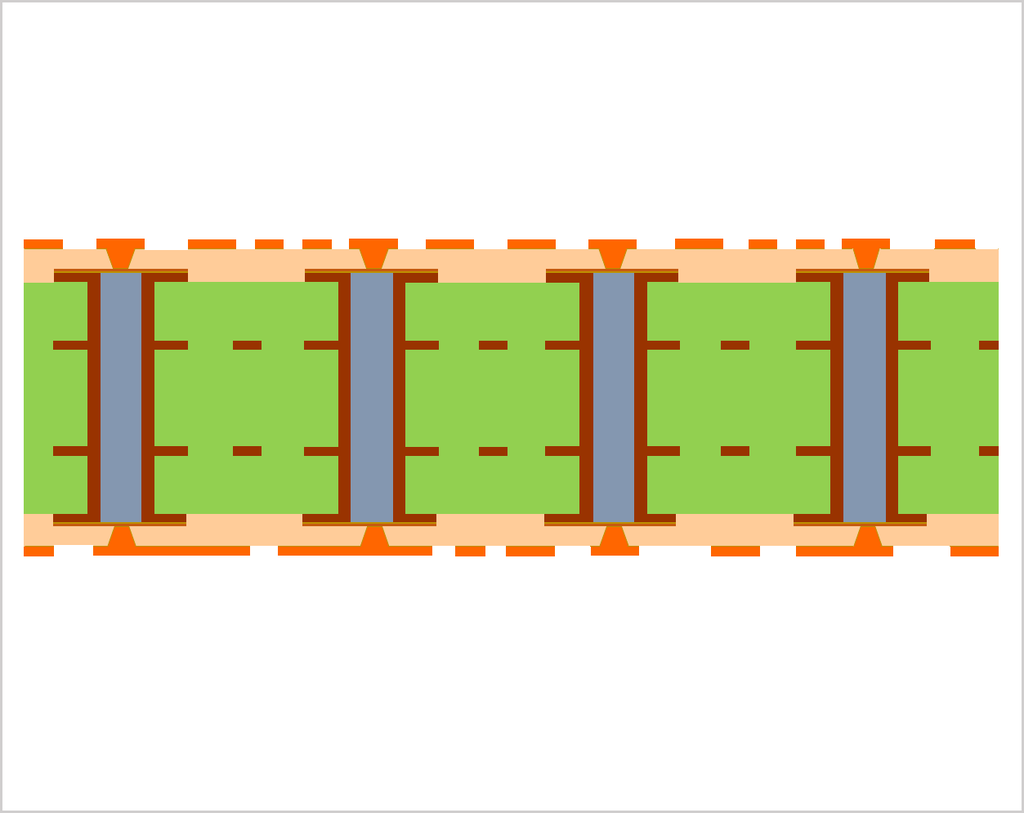

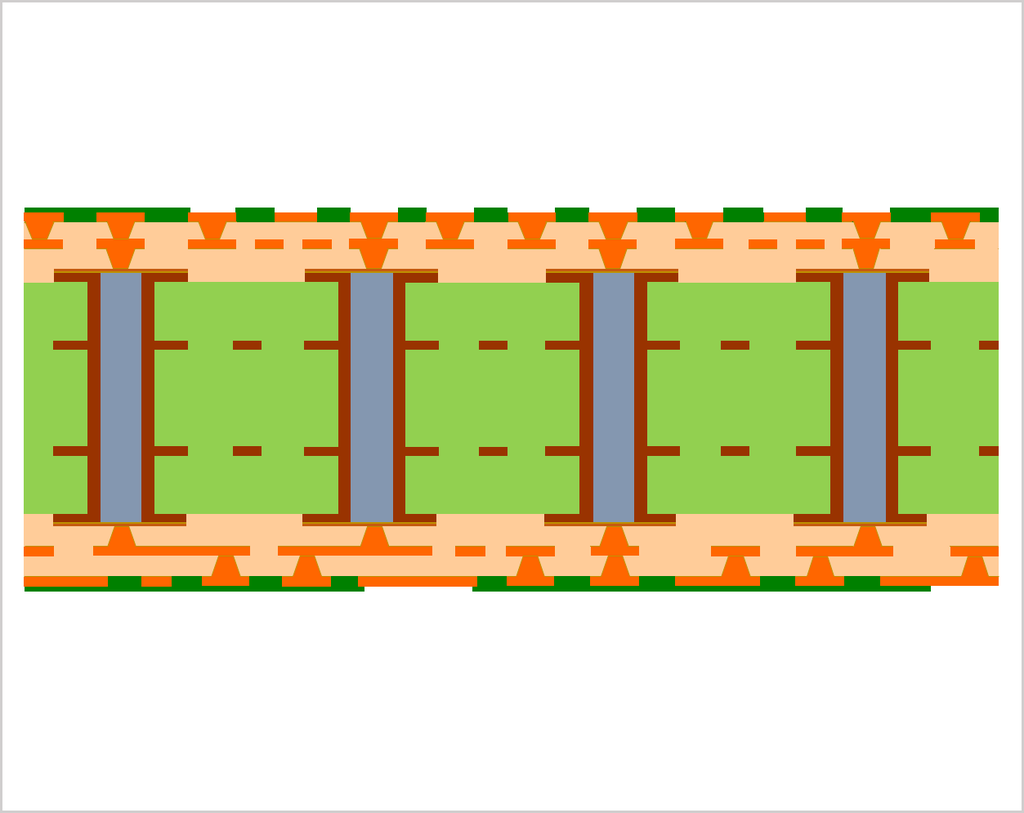

Dry the inks, and remove ink residues at the both sides of the printed wiring board.

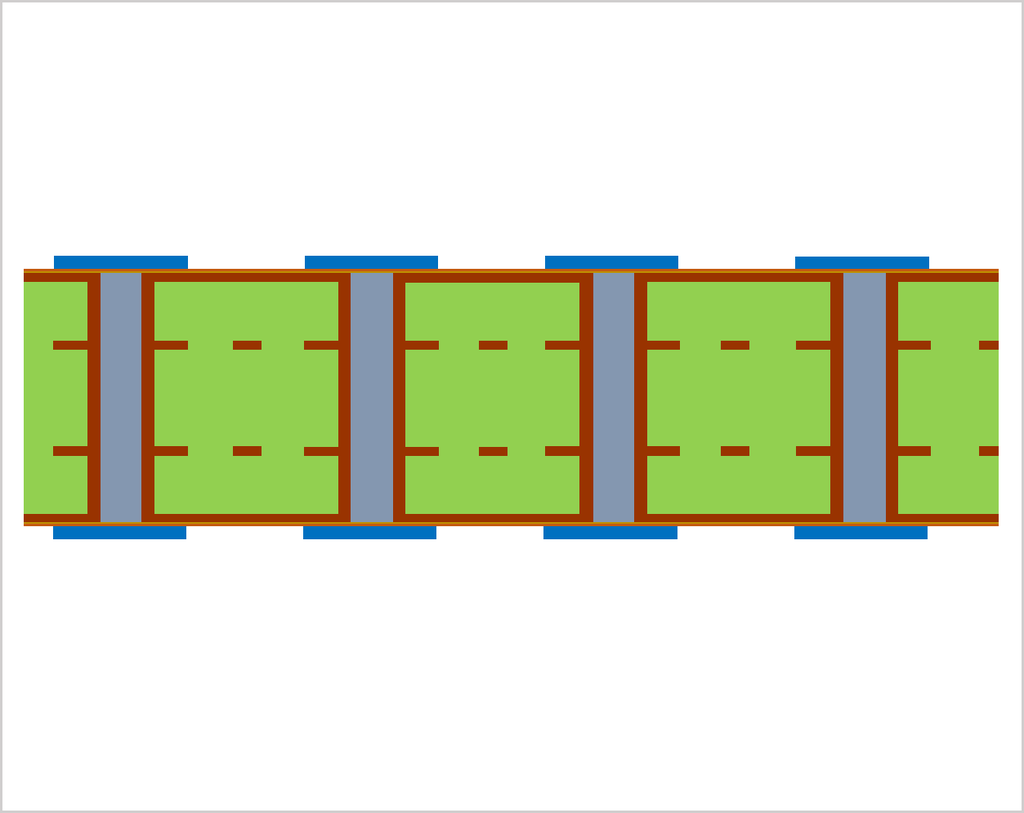

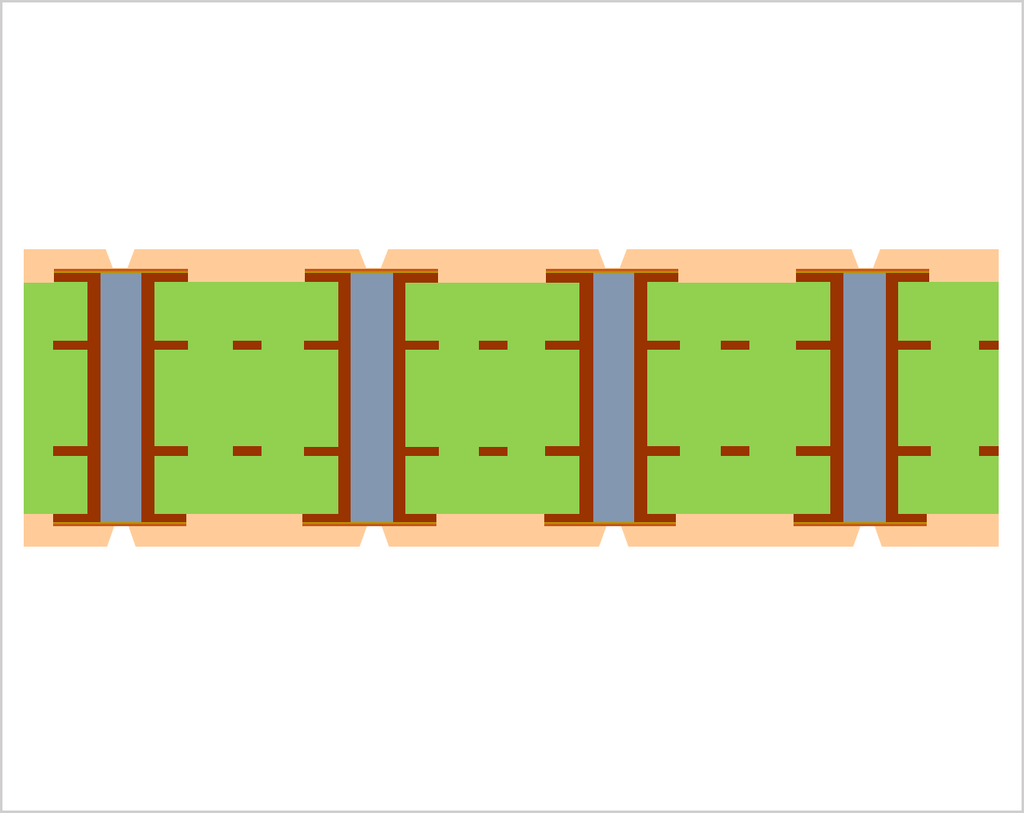

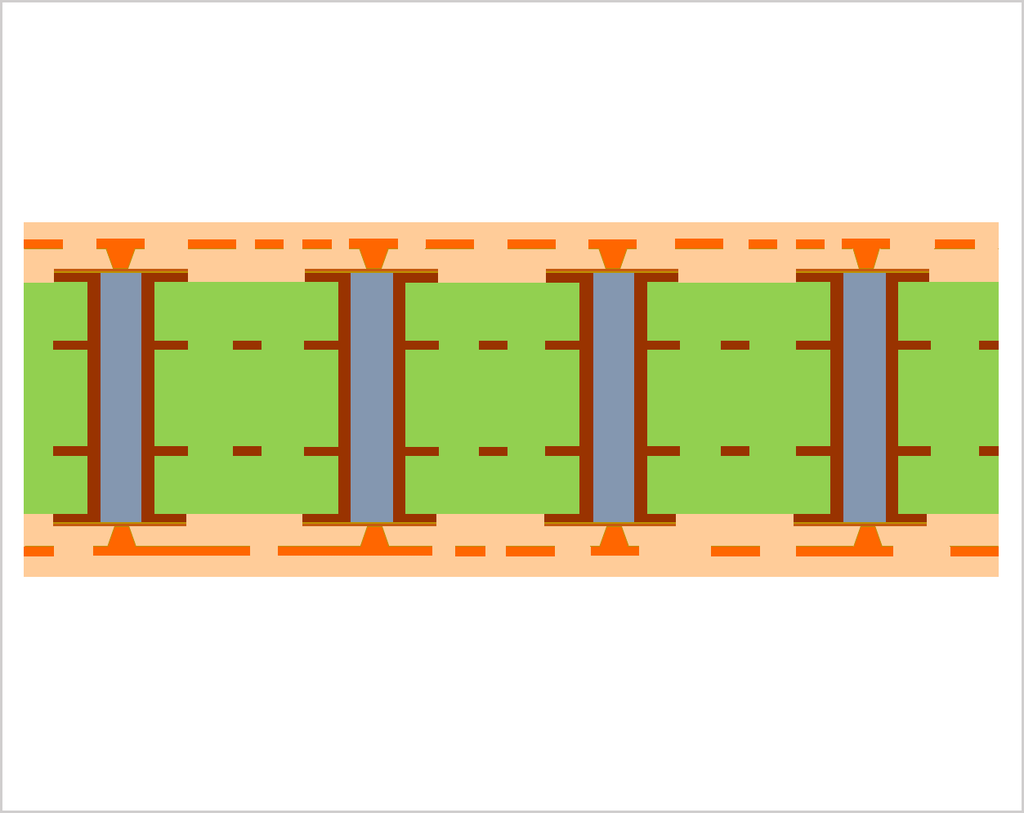

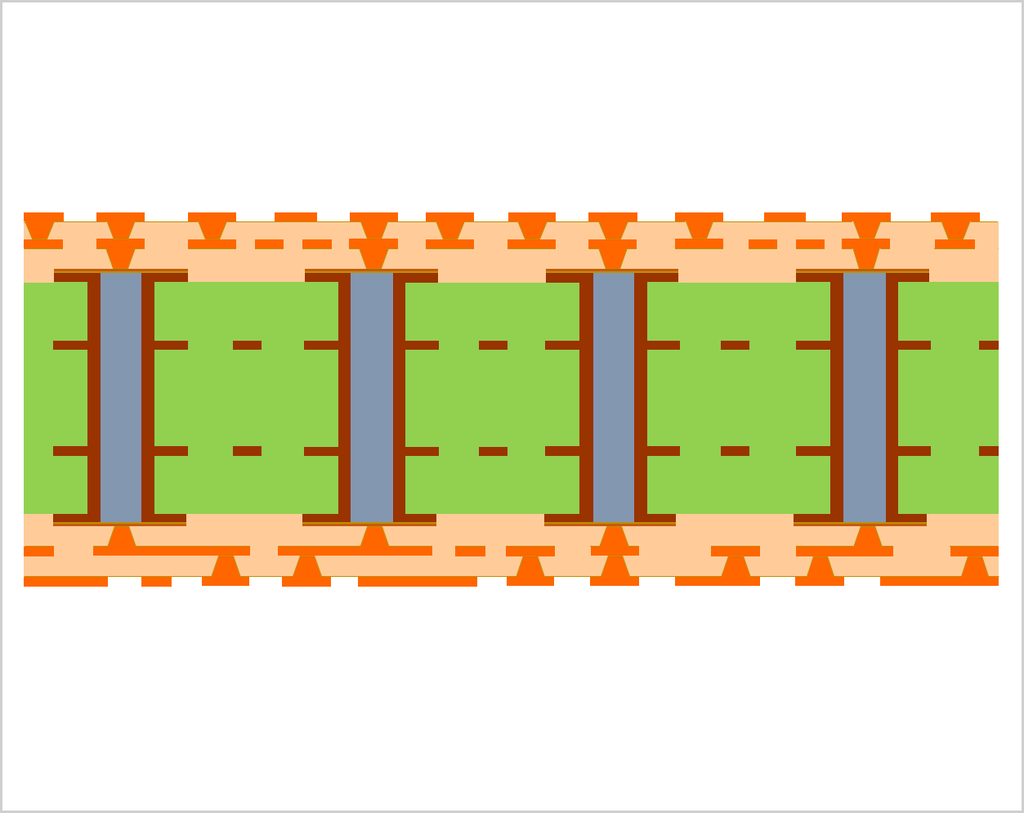

Completely cure the inks.

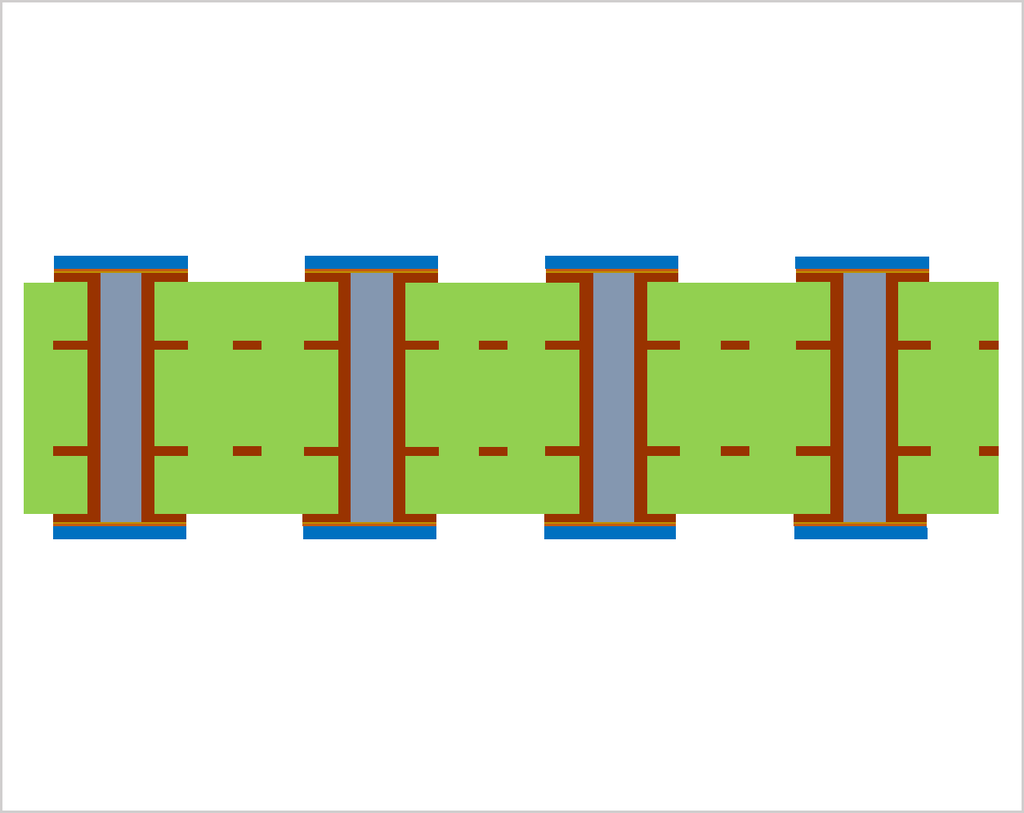

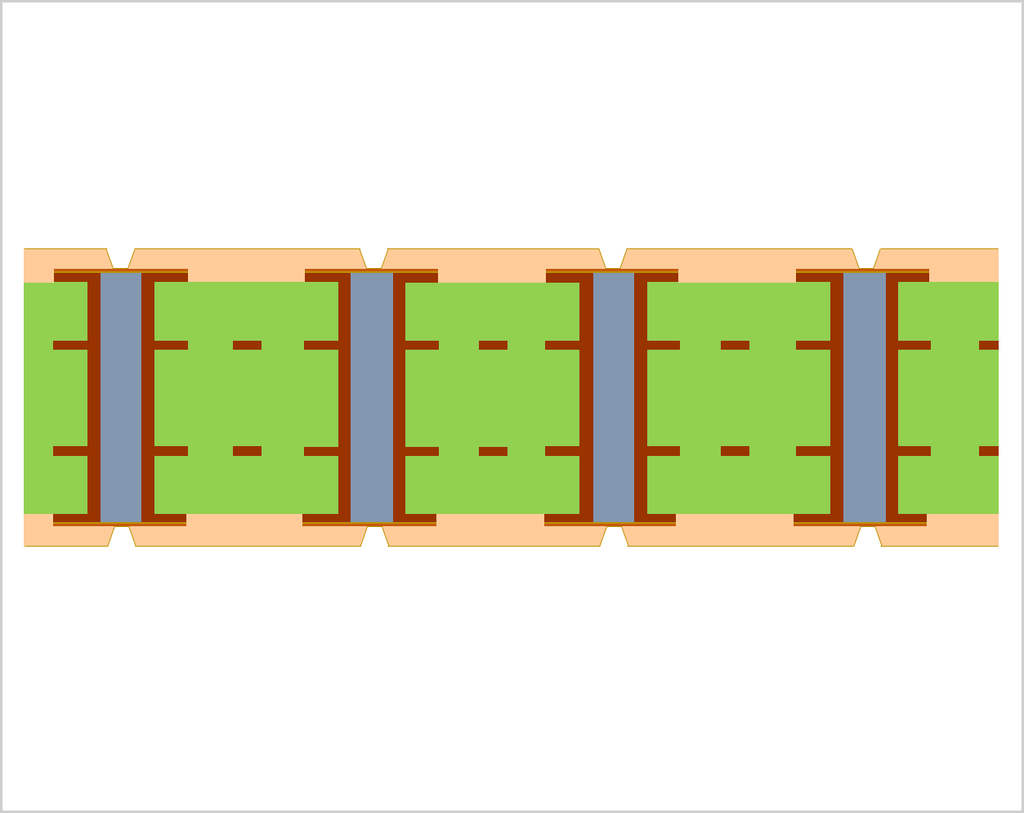

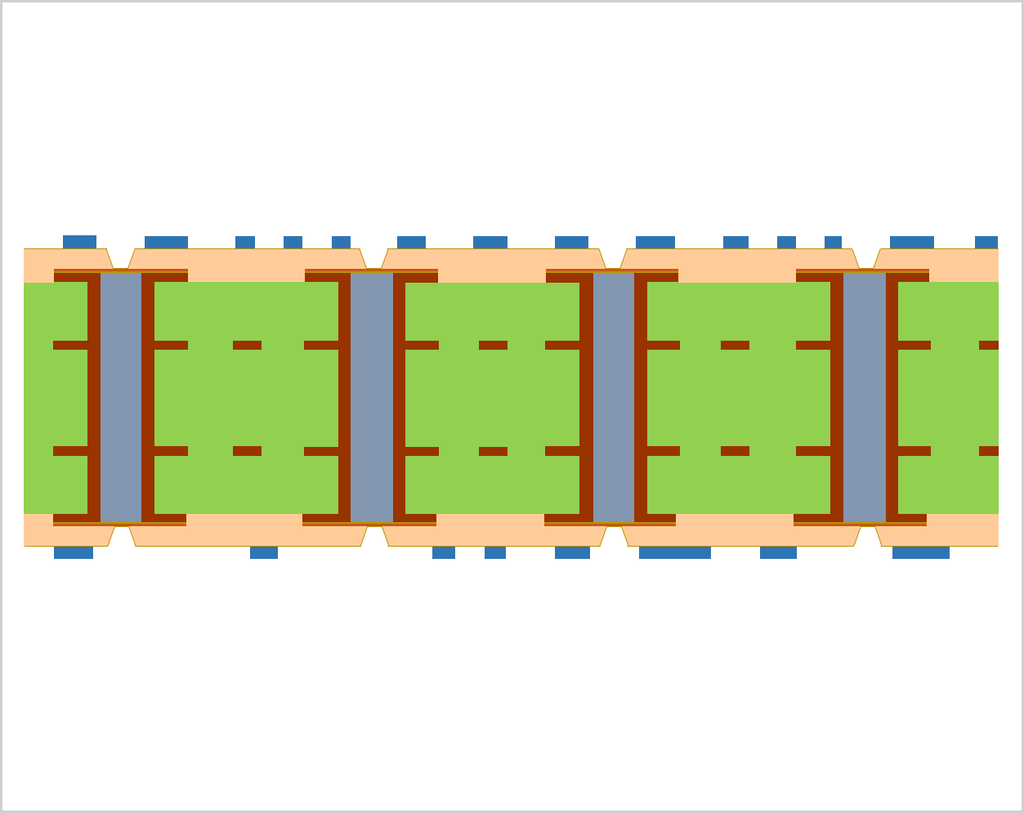

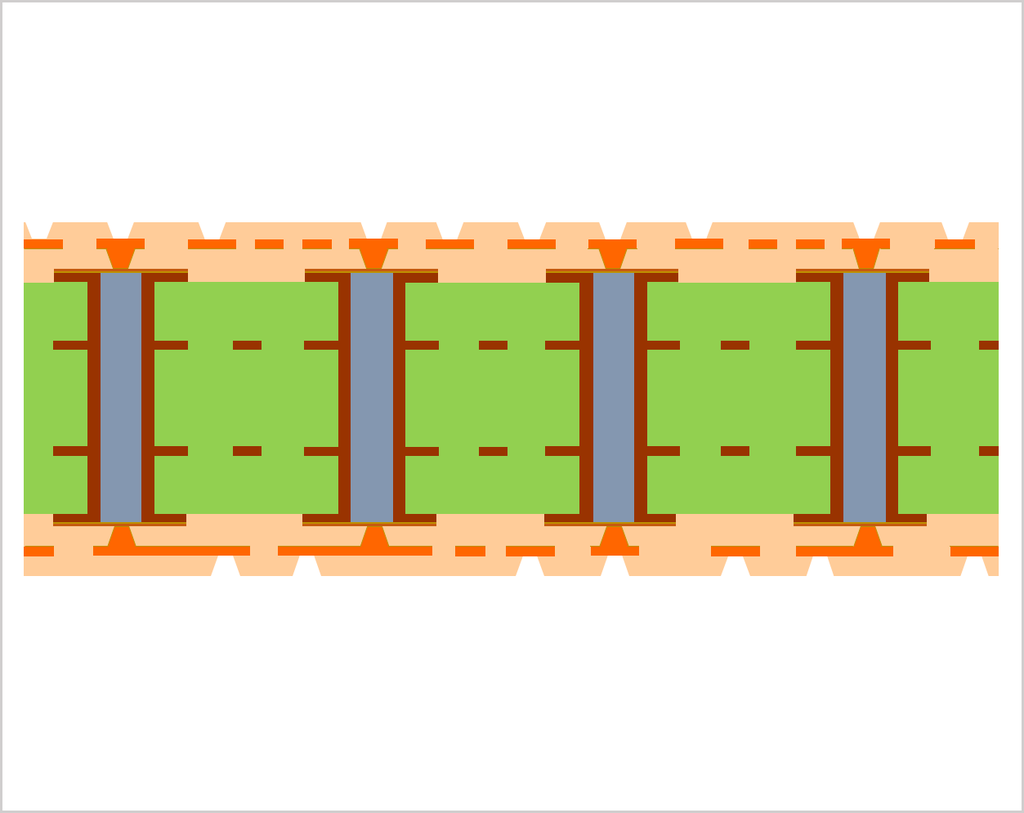

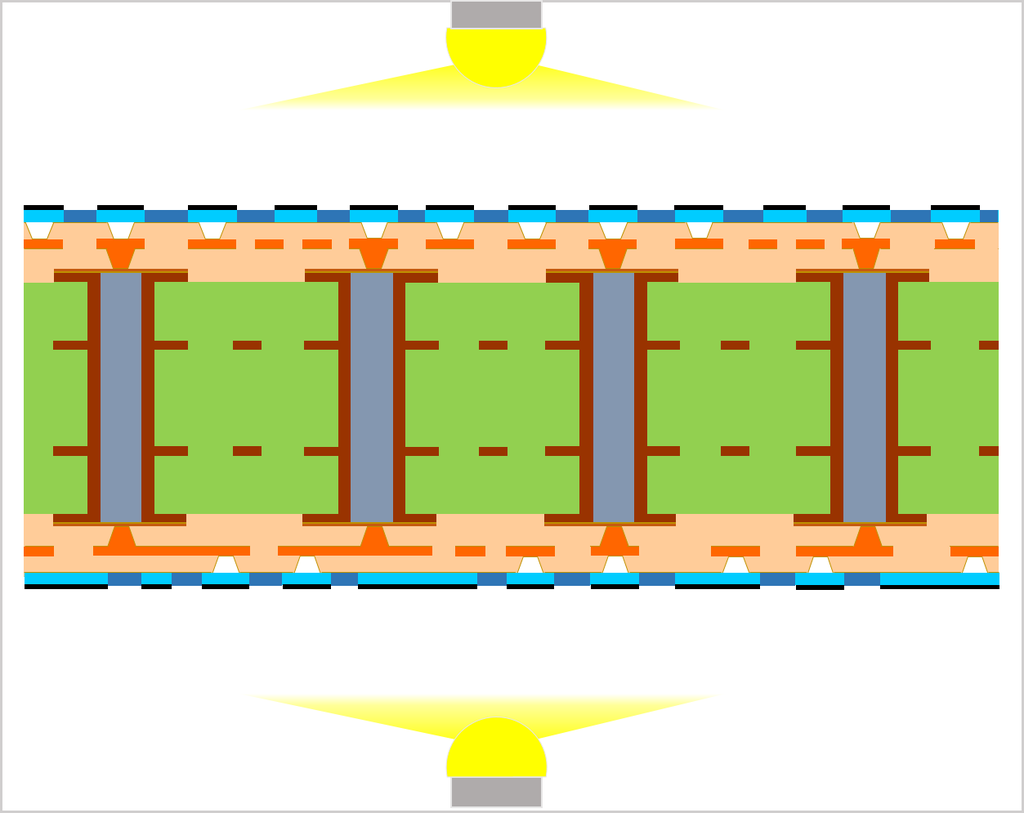

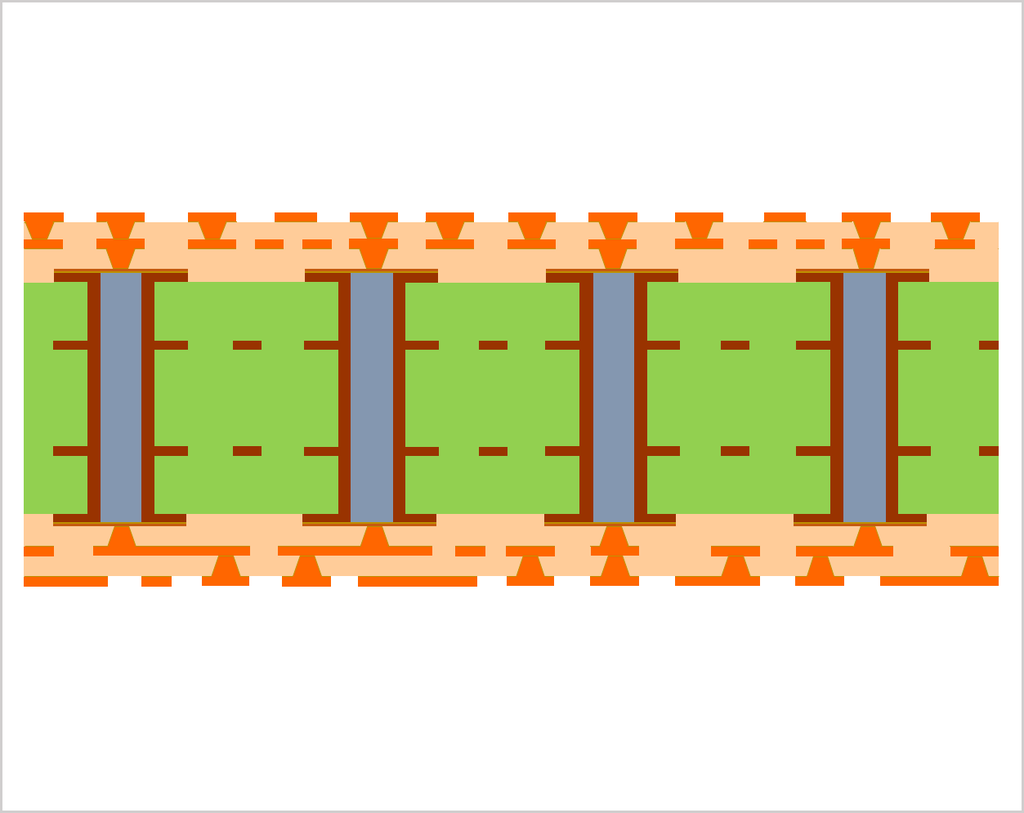

If through holes are fully filled by the copper electroplating, the steps from plug-in to electroless copper plating can be omitted.

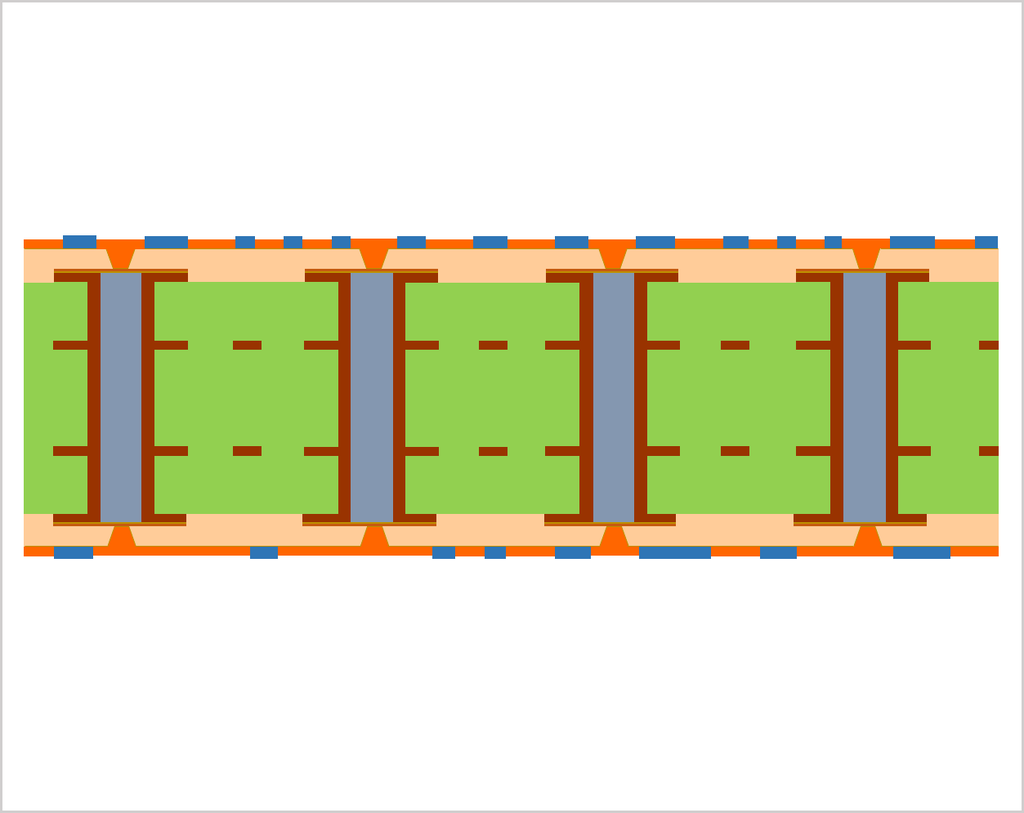

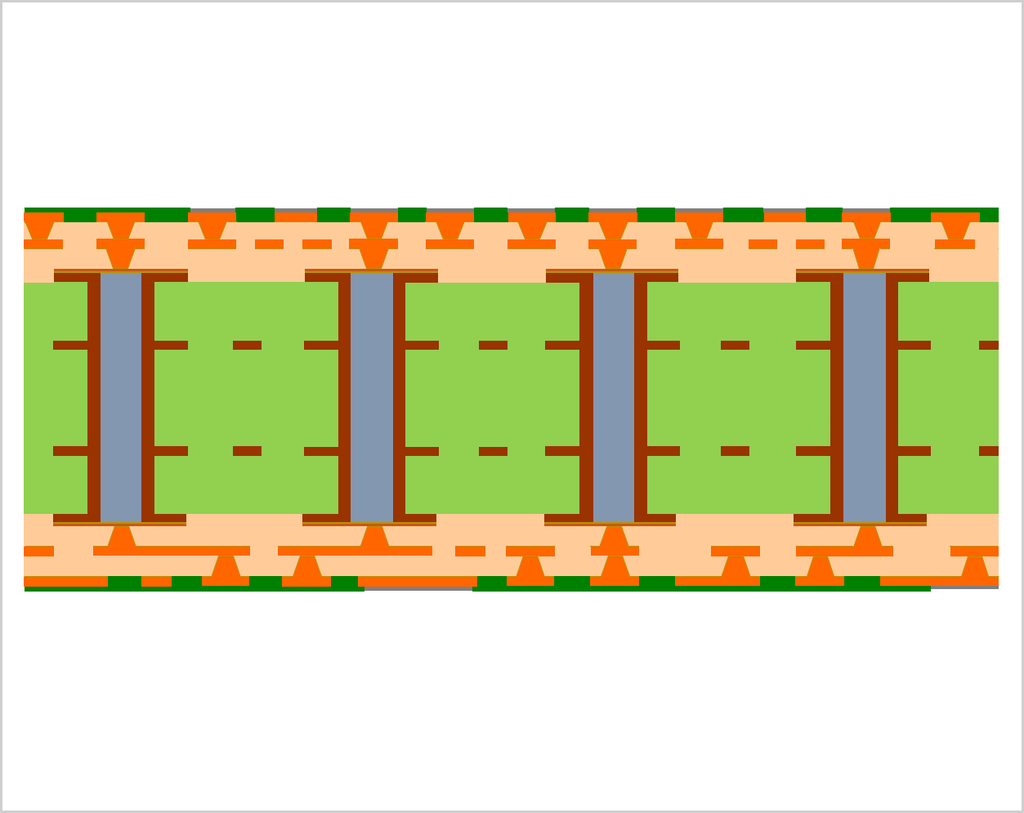

Also, filling by the electroplating can increase thermal conductivity, so some companies have made the filling by the electroplating practical.

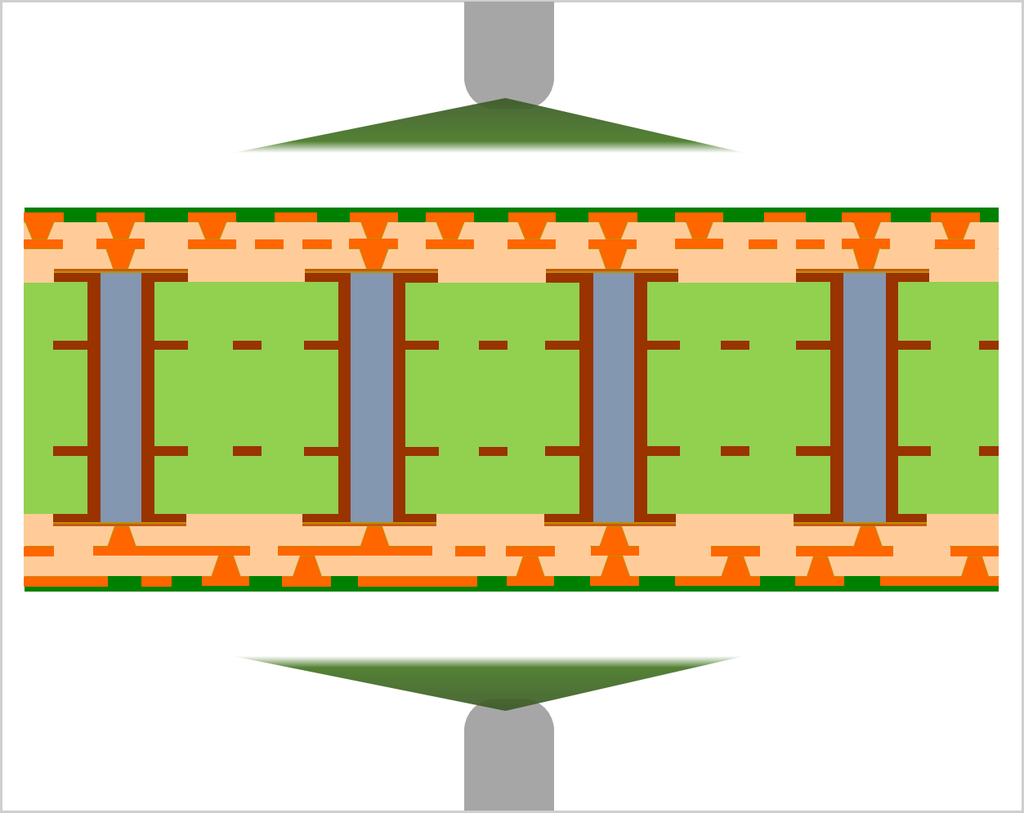

For full filling into through holes by the electroplating, we have TOP LUCINA LTF and related products.